- Homesteading

- Project Portfolio

- Pearls Place

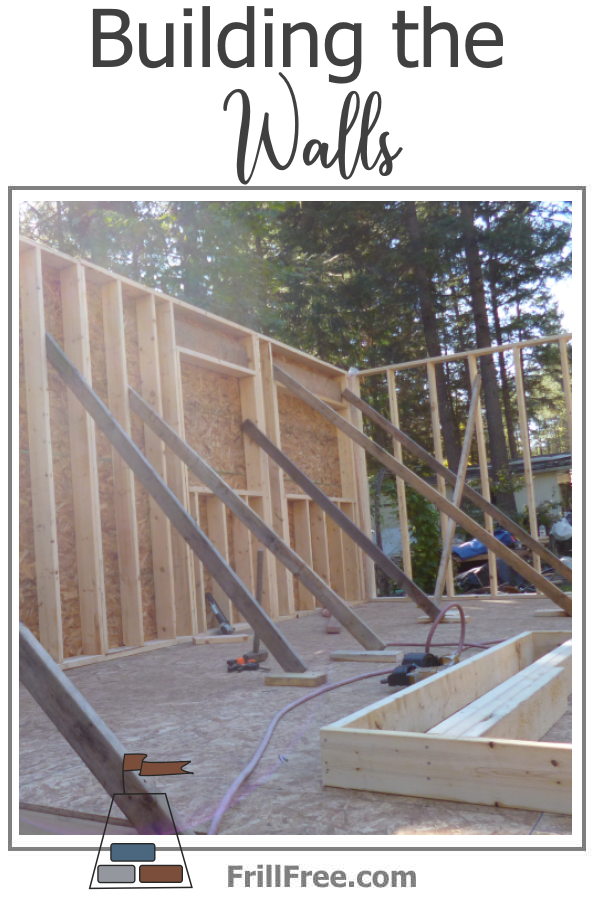

- Building the Walls

Building the Walls

Built in sections, raised by hand...

The walls of Pearls Place are built in sections, each large enough to get done quickly, but light enough for three guys to lift without straining.

Built out of 2x6 lumber, these could get unwieldy in a hurry; they are put together laid flat, using either a rechargeable drill and screws, or the air nailer which is run by a compressor.

The method used here is known as 'stick framing' which just means the wood is thinner than what people originally used for building their houses. It is a rather old fashioned term now, as there are few other methods used. Timber framing or cordwood, brick construction and log building are the few that come to mind.

Three people with good carpentry skills is ideal for this job - and someone in charge who can run a measuring tape very accurately. The potential for the project to go sideways in a hurry is always present; it's also important for everyone to be on their toes and make sure it's all the right way around.

See the pictures for more on building the walls, and standing them up;

A dry day is best for any kind of construction, for good footing and less chance of slippery surfaces.

A dry day is best for any kind of construction, for good footing and less chance of slippery surfaces.It also means less mud in the work area, and on the materials. Which translates to a lot less clean up at the end, always a good thing.

Each wall goes up in sequence, with window rough openings framed right in, based on the drawings of the project.

Each wall goes up in sequence, with window rough openings framed right in, based on the drawings of the project.The drawings by me were mostly just a quick line drawing, and a piece of drafting paper to show scale. I'm not an architect by any means. It's not essential for getting a building permit, so don't overthink it.

Lifting each section into place can be done with two people, but three is ideal to have two hold it, while the other toenails them into the floor.

Lifting each section into place can be done with two people, but three is ideal to have two hold it, while the other toenails them into the floor.There are lots of ways to make it easier, even with a small crew. Use fulcrums, bracing and chalk lines to get things in the right place, and aim for perfect first time.

They are set in place and jiggled to fit, and against the small boards nailed to the outside of the rim joist.

They are set in place and jiggled to fit, and against the small boards nailed to the outside of the rim joist.A lot of judicious kicking will get the walls into position, and then a quick blast with the air nailer to pin it in there.

Small adjustments might be necessary if it's hanging over the edge, or sticking out too far.

Small adjustments might be necessary if it's hanging over the edge, or sticking out too far.This you don't want. If it's too far out of line it will be impossible to work around it. So much easier to have to fur it out than to shave something off.

A good days work, with all the wall sections for the front and back in place and plumbed and squared. The angled braces hold everything in place.

A good days work, with all the wall sections for the front and back in place and plumbed and squared. The angled braces hold everything in place.Phew, another milestone reached. Two walls completed, tomorrow the front and back walls will be set in place.

A closer view of the bracing. Notice the rough openings for the windows - the OSB is not cut out until the windows are ready to install.

A closer view of the bracing. Notice the rough openings for the windows - the OSB is not cut out until the windows are ready to install.Skillful carpentry with a chainsaw will take out the holes for the windows - but not yet.

Another section goes up - this is the next day, so waiting until frost is off the floor might cause a delay. In some cases, a tarp would be put across the floor to prevent this.

Another section goes up - this is the next day, so waiting until frost is off the floor might cause a delay. In some cases, a tarp would be put across the floor to prevent this.Another day, and the weather is still fine. What are the odds?

You might notice a plume of smoke drifting over the worksite - we kept a small fire going so we could use it to cook our lunch. See more about cooking over a fire.

It's quite amazing how well this method of building works and how quickly it will go with a crew that cooperates and seems to read each others minds.

This is similar to old style barn buildings, where the whole community would show up in force to get things done.

It is understood that lunch will be supplied, and when it's time to turn to and help out the neighbors who showed up, it only takes a call. We loved being able to send out the word for assistance to our crew and volunteers.

Knowing what the next step will be without a lot of chatter, Mike, Terry and Rod all got the job done quickly and with a minimum of fuss...see the next stage here; the trusses...